- Joined

- Jan 20, 2004

- Messages

- 30,613

- Reaction score

- 19,670

"

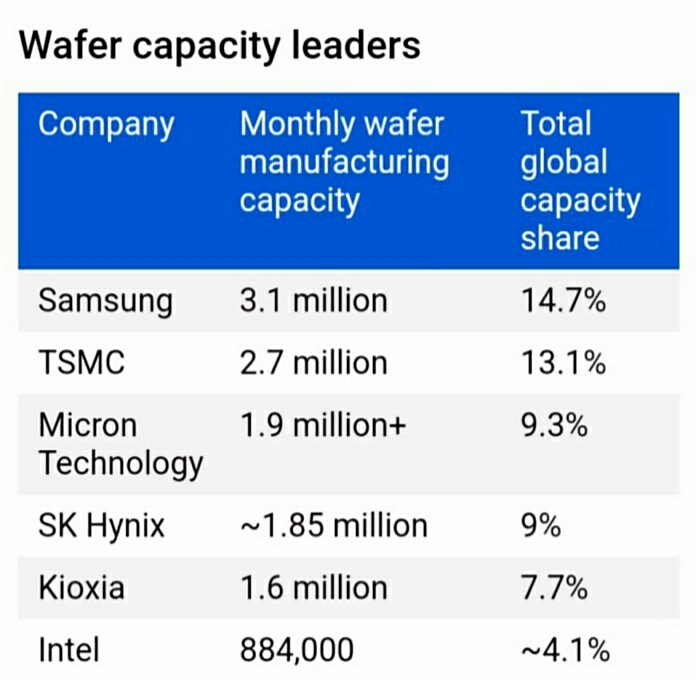

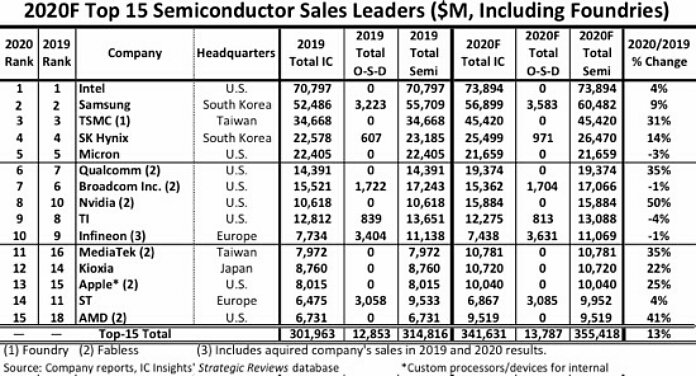

In context: We know that as part of its IDM 2.0 initiative, Intel is aiming to compete with semiconductor manufacturing giants TSMC, Samsung, and other rivals by 2025. To achieve this goal, it is building a mega-fab in the US—and it's going to be big: costing between $60 billion - $120 billion and creating tens of thousands of jobs.

Back in March, CEO Pat Gelsinger's announced that Intel would open up both its current and planned manufacturing capacity to other chipmakers through the launch of Intel Foundry Services (IFS); its first customers will be Snapdragon SoC maker Qualcomm and Amazon. The company is also planning to build a new mega-fab at a yet-to-be-decided location in the US."

Intel says its US mega-fab will be a $120 billion "little city"

"I want to build factories a lot faster than we can today," said CEO Pat Gelsinger

By Rob Thubron August 9, 2021 8

Back in March, CEO Pat Gelsinger's announced that Intel would open up both its current and planned manufacturing capacity to other chipmakers through the launch of Intel Foundry Services (IFS); its first customers will be Snapdragon SoC maker Qualcomm and Amazon. The company is also planning to build a new mega-fab at a yet-to-be-decided location in the US.

, Gelsinger revealed some specifics of this project. It's going to be a huge site consisting of six to eight fab modules, each costing between $10 billion to $15 billion. That means the final cost of construction will be between $60 billion - $120

"It's a project over the next decade on the order of $100 billion of capital, 10,000 direct jobs. 100,000 jobs are created as a result of those 10,000, by our experience. So, essentially, we want to build a little city," Gelsinger said.

Intel is still looking at several sites across a number of states as potential mega-fab locations. Not only must it consider energy, water, and environmental factors, but it also wants the project to be near a university to attract skilled staff.

There were some details Gelsinger didn't reveal, including which nodes the initial module of the mega-fab will support. Given that operations are expected to start in 2024, we can expect Intel 4 (previously referred to as 7nm) and Intel 3 (7+) before moving onto its more advanced 20A process—the company's first to use its "RibbonFET" version of Gate-All-Around (GAA) transistors.

https://www.google.com/amp/s/www.te...ntel-us-mega-fab-120-billion-little-city.html

In context: We know that as part of its IDM 2.0 initiative, Intel is aiming to compete with semiconductor manufacturing giants TSMC, Samsung, and other rivals by 2025. To achieve this goal, it is building a mega-fab in the US—and it's going to be big: costing between $60 billion - $120 billion and creating tens of thousands of jobs.

Back in March, CEO Pat Gelsinger's announced that Intel would open up both its current and planned manufacturing capacity to other chipmakers through the launch of Intel Foundry Services (IFS); its first customers will be Snapdragon SoC maker Qualcomm and Amazon. The company is also planning to build a new mega-fab at a yet-to-be-decided location in the US."

Intel says its US mega-fab will be a $120 billion "little city"

"I want to build factories a lot faster than we can today," said CEO Pat Gelsinger

By Rob Thubron August 9, 2021 8

- 124

- Comments

Back in March, CEO Pat Gelsinger's announced that Intel would open up both its current and planned manufacturing capacity to other chipmakers through the launch of Intel Foundry Services (IFS); its first customers will be Snapdragon SoC maker Qualcomm and Amazon. The company is also planning to build a new mega-fab at a yet-to-be-decided location in the US.

, Gelsinger revealed some specifics of this project. It's going to be a huge site consisting of six to eight fab modules, each costing between $10 billion to $15 billion. That means the final cost of construction will be between $60 billion - $120

"It's a project over the next decade on the order of $100 billion of capital, 10,000 direct jobs. 100,000 jobs are created as a result of those 10,000, by our experience. So, essentially, we want to build a little city," Gelsinger said.

Intel is still looking at several sites across a number of states as potential mega-fab locations. Not only must it consider energy, water, and environmental factors, but it also wants the project to be near a university to attract skilled staff.

There were some details Gelsinger didn't reveal, including which nodes the initial module of the mega-fab will support. Given that operations are expected to start in 2024, we can expect Intel 4 (previously referred to as 7nm) and Intel 3 (7+) before moving onto its more advanced 20A process—the company's first to use its "RibbonFET" version of Gate-All-Around (GAA) transistors.

https://www.google.com/amp/s/www.te...ntel-us-mega-fab-120-billion-little-city.html